|

| Product Technical Information |

Sprayable

Superfine Tungsten Carbide Cobalt – Infralloy™ Powder S7400 Series [U.S. Patent Nos. 6,025,034 6,277,448 6,277,774 6,287,714] |

| Thermal Spray Grade | Tungsten carbide cobalt is a ceramic-metal (cermet) composite material used as a wear resistant coating. The alloyed form gives superior hardness. Infralloy™ powder is made from WC nanoparticles alloyed with a cobalt binding matrix phase. | Infralloy™ Series S7400 powder is available as agglomerated particles with dimension 5 < F < 45 mm with high flowability for HVOF thermal spray applications. |

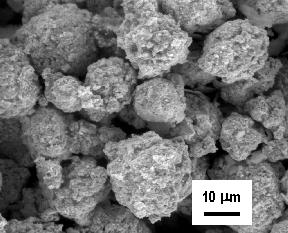

| Morphology |

|

| SEM micrograph typical of Infralloy™ S7412 feedstock powder showing spherical geometry with high flowability. |  |

| Properties of Infralloy™ S7400 Series Powders | S7412 | S7417 |

| WC : Co wt ratio | 88 : 12 | 83 : 17 |

| Alloy content | < 1 % | < 1 % |

| powder grain size (ave.) | 50 - 500 nm | 50 - 500 nm |

| agglomerated powder size | 5 < Φ < 45 μm | 5 < Φ < 45 μm |

| coating hardness (typical) | 1100 VHN | 900 VHN |

|

1 nanometer (nm) = 10 – 9 meter (m) |

||

|

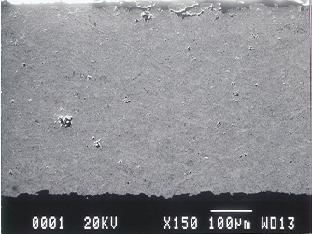

Coating Microstructure |

||

| Cross sectional SEM view of a typical very dense carbide coating produced by a Metco HVOF gun using Infralloy™ S7412 feedstock powder. Pores (dark spots) occupy only ~ 1% volume. |  |

|

| Suggested Applications |

||

| Inframat Infralloy™ S7400 Series powder is a superior coating material providing wear-, erosion-, and corrosion-resistant surfaces where excellent to exceptional fracture toughness is required. | ||

| S7400 Series | Coating Types | Fracture Toughness |

| S7412 | Wear-, Erosion-, Corrosion-Resistant | Excellent |

| S7417 | Wear-, Erosion-, Corrosion-Resistant | Exceptional |

The Thermal Spray Grade material can be applied with DC Arc plasma and HVOF guns. Full spray specifications are available through Technical Applications Bulletins Nos. S7412.01B and S7417.01B.